The journey of wood pulp, from its origins in the forest to its transformation into paper products, is a complex and vital process that underscores the paper industry’s reliance on effective shipping logistics. As one of the most renewable resources, wood pulp is harvested from sustainably managed forests, where trees are carefully selected and felled to minimize ecological impact. Once harvested, the wood is transported to pulp mills, where it undergoes processing to produce pulp—the raw material essential for paper production. The shipping of wood pulp is a multi-faceted operation involving various modes of transportation, including trucks, trains, and ships. Each stage of transportation plays a critical role in ensuring that the pulp reaches its destination efficiently and economically. Trucks are often used for the initial transport from logging sites to processing mills, offering flexibility in accessing remote locations.

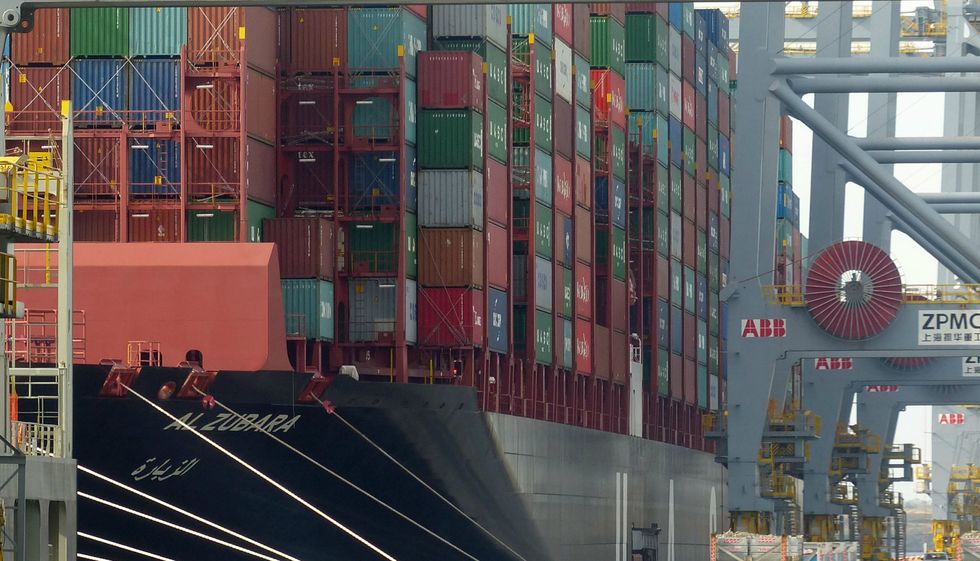

Once the pulp is processed, it can be transported to paper mills through a combination of rail and maritime shipping, allowing for bulk transport over long distances. This logistical strategy not only reduces transportation costs but also helps minimize the carbon footprint associated with the shipping process. Maritime shipping, in particular, is integral to the global paper industry, especially as the demand for paper products continues to rise in developing economies. Major producers of wood pulp, such as Brazil, Canada, and the United States, often export their products to countries like China and India, where demand for paper has skyrocketed. Efficient shipping routes and modern container ships enable the swift movement of wood pulp across oceans, ensuring that production schedules at paper mills are met without significant delays. Moreover, advances in technology have enhanced the efficiency of wood pulp shipping. The use of tracking systems allows companies to monitor shipments in real time, providing transparency and facilitating better decision-making.

Automated logistics management systems further streamline operations, ensuring that the pulp arrives at the right location and at the right time. These technological improvements not only reduce operational costs but also contribute to the sustainability goals of the industry by optimizing transport routes and minimizing waste. However, the wood pulp shipping process is not without challenges. Fluctuating fuel prices, Container shipping for forest products regulatory changes, and environmental concerns can impact logistics and costs. The industry must continually adapt to these challenges, ensuring that it remains competitive while adhering to sustainable practices. Wood pulp shipping is a cornerstone of the paper industry, facilitating the movement of this essential raw material from forest to factory. Through efficient logistics, modern technology, and a commitment to sustainability, the paper industry continues to thrive, meeting global demand while minimizing its ecological impact.